Product

Classification

LN82 Series Single Seat Globe Pneumatic Control Valve

Introduce : LN82 series are LN8 series pressure imbalance structure products one of two basic bus

- Product

- Parameter

Product Overview

Globe Control Valves use linear motion to move the shutoff member in and out of the seat surface. Their bodies feature a spherical cavity around the port area and are designed to regulate process flow when used in conjunction with an actuator assembly. Many single-seat bodies use a cage, three-way or fixed construction to hold the seat ring in place, provide spool guidance, and provide a means of establishing specific valve flow characteristics. Caged or fixed single-seat bodies can also be easily modified by replacing the internals to change the flow characteristics or to provide reduced capacity flow, noise attenuation, or to reduce or eliminate cavitation.

The LN8 series top-guided single-seat control valve is a top-guided, plunger-type single-seat control valve. It was certified by TÜV ISO15848 in 2019. It has the characteristics of high control accuracy, good sealing performance, simple structure and high versatility. Suitable for fluid control in globe control valve working conditions requiring high control accuracy. Bellows seal type can be used. Thousands of applications in the fine chemical, petrochemical, pharmaceutical and other industries.

Performance advantages

Modular design concept, combining the American and Japanese schools of high-precision control and the German school of modular concept.

The inner cavity of the valve body is S-shaped distribution, smooth and without dead corners; the valve body has internal flow guide wings, which can reduce the mutual force of the medium inside the valve body and reduce the occurrence of cavitation.

Simple structure, less dead space in the internal globe control valve parts, reducing the possibility of crystallization and blockage of the medium.

The valve spool adopts upper guidance, which is smoothly guided.

The valve seat adopts floating design, while the sealing surface adopts tapered form to ensure good alignment of the sealing vice.

Spool type face control flow characteristics, accurate flow characteristics control.

Equivalent percentage, linear and fast-opening flow characteristics are available.

Temperature range of application span, -196 ~ 593 ℃ are available in the appropriate structure.

Leakage grade meets GB/T 17213.4-2005 / IEC 60534-4:1999, hard seal up to grade IV, V, fast-opening and soft seal up to grade VI; and pipeline connection with RF, RJ, FM and other flange types and SW, BW welding type.

The flange distance conforms to GB/T 17213.3-2005 / IEC 60534-3-1:2000; or ISA S75.03-1992 standard.

Long life

1. Valve Trims

According to the needs of the working conditions, different materials and surface hardening treatment can easily be chosen to meet the requirements of each function module of trim to improve its performance of the corrosion, cavitation and erosion resistant, lengthen service life.

2. Valve body

The body of LN8 series control valves consists of two passages from upper and lower, forming a shape like letter "S". The design of an elliptical section reduces the flow resistance and turbulent flow to keep the flow fluent. The flap in the middle of upper passage can reduce the eddy flow and increase the flow capacity.

LN81 Series Single Seat Globe Control Valve

3. pneumatic actuator of globe control valve

The standard mate of LN8 series is AM8 Multi-spring pneumatic diaphragm actuator, which can be used in many conditions with the features of strong output force, high reliability, long lifespan and extensive application. The output force changes with the number of springs. The high stress resistant diaphragm, bearing maximum pressure of 0.5 MPa air supply, gives control valve a reliable shutoff. This type of actuator has a long life cycle with more than 1 million times.

Well Sealed

1. Structure

A. New function modular design B. Self-centring seat design

2. Packing system

The packing box assemblies are also optimized. Seal ring in the gland flange can prevent the dirt from entering and protect the packings. The V-ring is added with an U-groove and its angle is changed from conventional 90 to more efficient 85. The packing is a combination of alternating pure PTFE and PTFE with grafoil. When the temperature of fluid is above 200℃, the packing will be made by grafoil.

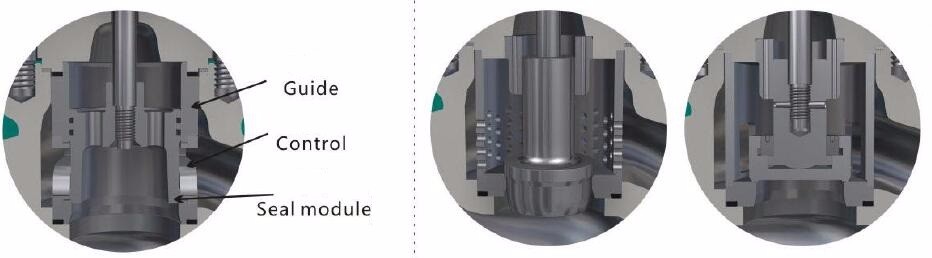

High Precision

LN8 series automated globe control valve are designed strictly on the basis of the IEC standard. They are the latest self-innovated modularized straight stroke control valve of SUPCON. We divide the trims into three modules, namely guide, control and seal module. We provide the best solution according to the function of each module and make action, control and seal more reliable.

Each index, linear, hysteresis, dead zone and leakage, for example, is full compliance with national standards.

Note: For below measured results, take LN8100 top guide single seat valve (PN110) as an example.

Test Items | National Standard | SUPCON Standard | Measured Results |

Seat Leakage | 0.06 L/min | 0.064 L/min | 0.01L/min |

Rated Travel Error | +2.5% | +2% | 1.32% |

Start Error | ±2.5% | ±2% | 0% |

End Error | ±2.5% | ±2% | 0.08% |

BasicError | ±1.5% | ±1% | -0.52% |

Hysteresis | 1.5% | 1% | 0.16% |

Dead Band | 0.6% | 0.4% | 0.38% |

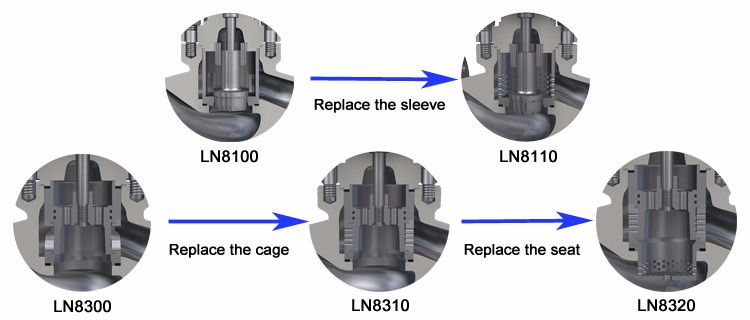

Easy to maintain

The unique platform and modul design make it easy to remove and displace the parts without special tools, and moreover, easy to change the type of the valve only by changing few parts. A variety of material combinations is optional for the parts.

Nominal diameter: DN15/20/25/32/40/50/65/80/100/125/150/200/250/300

Pressure rating: ANSI CL150/300/600; DIN PN16/25/40/63

Valve body and upper bonnet material: WCB, WC6, WC9, CF8, CF8M, etc.

Upper bonnet form: standard type (-17℃~+316℃); high temperature type (+316℃~+593℃); low temperature Ⅰ type (-45℃ ~ -17℃)

Low temperature Ⅱ type (-100 ℃ ~ -45 ℃); low temperature Ⅲ type (-196 ℃ ~ -100 ℃); bellows type (-45 ℃ ~ +350 ℃)

Packing type: PTFE + graphite V-shaped packing; flexible graphite ring packing; graphite + PTFE preparation packing; etc.

Flow characteristics: equal percentage (%); linear (L); quick-open (Q)

Adjustable ratio: 50:1,100:1(optional)

Allowable leakage: metal seal: ANSI B16.104 Class Ⅳ/V; soft seal: ANSI B16.104 Class Ⅵ

TECHNICAL PARAMETERS

| Nominal Size | DN25 ~ DN200 |

| Pressure Rating | PN16/25/40/63/100;CL150(PN20)/300(PN50)/600(PN110) |

| Operateing Temperature | -196℃~ 593℃ |

| Characteristics | Equal percentage, linear |

| Rangeability | 50:1 |

| Seat Leakage Class | ANSI B16.104: IV、V、VI |

| Body Material | WCB/WCC/LCB/LCC;WC6/WC9;CF8/CF8M;4A/5A etc. |

| Trim Material | 630/316/316+ST/316nitriding/316+Ni60/316+WC etc. |

| Seal Material | PTFE+ graphite v-shaped packing, flexible graphite ring packing, graphite +PTFE braided packing etc. |

TECHNICAL PARAMETERS

| Nominal Size | DN25 ~ DN200 |

| Pressure Rating | PN16/25/40/63/100;CL150(PN20)/300(PN50)/600(PN110) |

| Operateing Temperature | -196℃~ 593℃ |

| Characteristics | Equal percentage, linear |

| Rangeability | 50:1 |

| Seat Leakage Class | ANSI B16.104: IV、V、VI |

| Body Material | WCB/WCC/LCB/LCC;WC6/WC9;CF8/CF8M;4A/5A etc. |

| Trim Material | 630/316/316+ST/316nitriding/316+Ni60/316+WC etc. |

| Seal Material | PTFE+ graphite v-shaped packing, flexible graphite ring packing, graphite +PTFE braided packing etc. |