Product

Classification

Best plate heat exchanger for beer brewery

Introduce :

- Product

- Parameter

Best plate heat exchanger for beer brewery

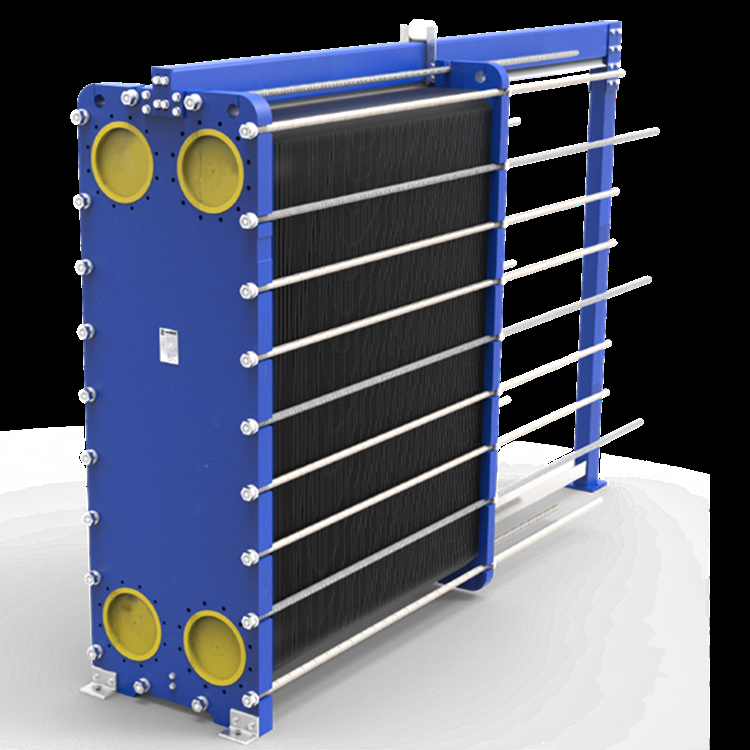

The WEMAC plate heat exchanger (PHE) series is extensive, including multiple types of heat exchangers, suitable for all types of industries, with multiple applications, including heating, cooling, condensation and evaporation. Our design factors give PHE the flexibility to ensure the best fit, can be expanded to meet future needs, and can be easily adjusted to accommodate changes in capacity.

Our traditional plate heat exchanger is the first choice for standard tasks. Multifunctional design and high thermal efficiency make them a perfect solution for a wide range of applications.

What does this mean to you-Best plate heat exchanger for beer brewery

We focus on developing plate heat exchangers in close cooperation with our customers. Because we understand the process behind your application, each solution is customized and configured to suit you and your business.

Our extensive printing plate product portfolio and pattern options ensure that we always have a solution that is perfectly suitable for you. Our model creates ideal turbulence and makes full use of the available pressure drop in any task.

Always an efficient choice

We design one-way solutions as much as possible because they are the first choice for almost all tasks. Since all connections are at the head, you can inspect, clean or repair without disconnecting the heat exchanger from the pipe. With WEMAC heat exchanger, installation and maintenance are simple, fast and convenient.

The design space requirement of WEMAC heat exchanger is extremely small, energy consumption is significantly reduced, and the number of plates required to achieve the best performance is reduced, so the future is considered in the design.

Advantage-Best plate heat exchanger for beer brewery

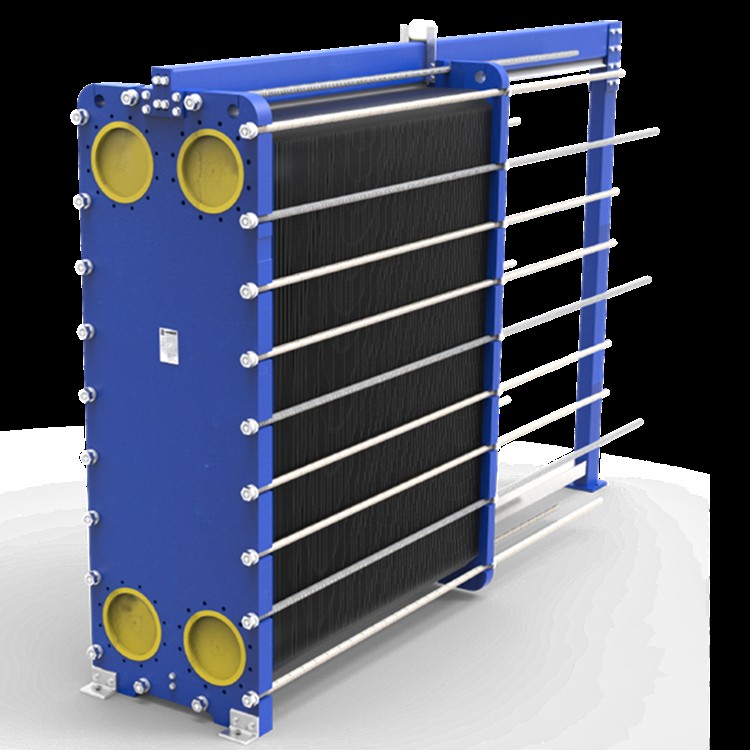

Compact design requires less space than shell and tube

Large heat exchange area

Scalable solutions because they can increase heat transfer by adding more plates

The temperature can be controlled even in small differences

Avoid cross-contamination by ensuring the special function of preventing the mixing of two process fluids

PHE requires less volumetric flow, which means lower costs in terms of space, pipes and pumps

Due to higher turbulence, less fouling

Easy to maintain, no extra space for disassembly

Specially designed high-efficiency fluid distribution with corrugated pattern to ensure the highest overall heat transfer rate

Durable gasket, ergonomic design, easy to maintain.

Application-Best plate heat exchanger for beer brewery

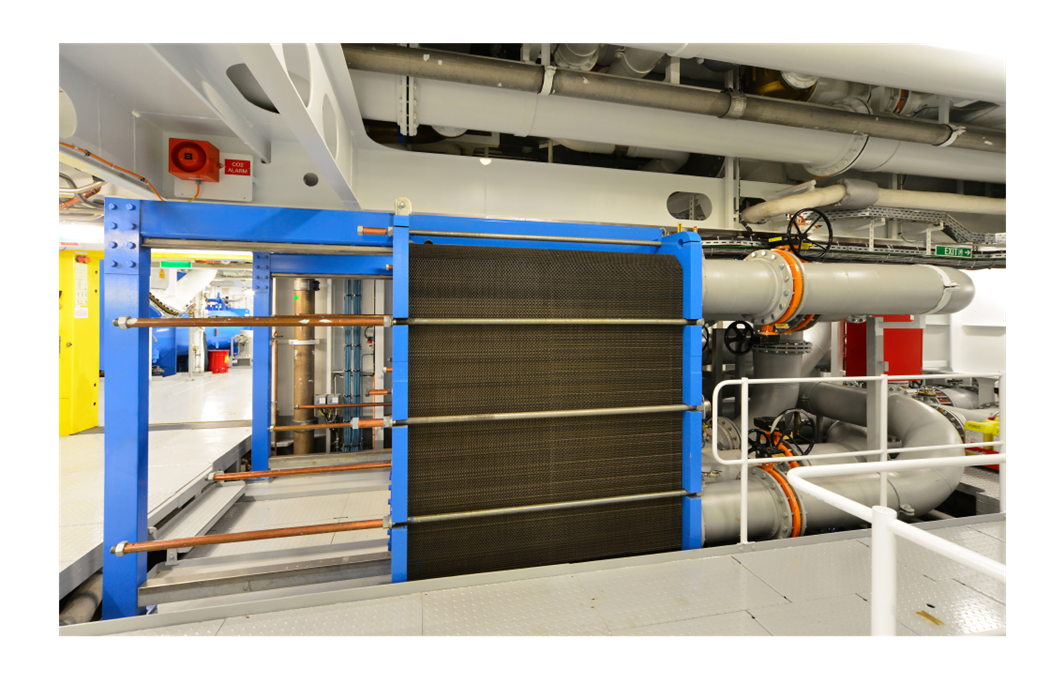

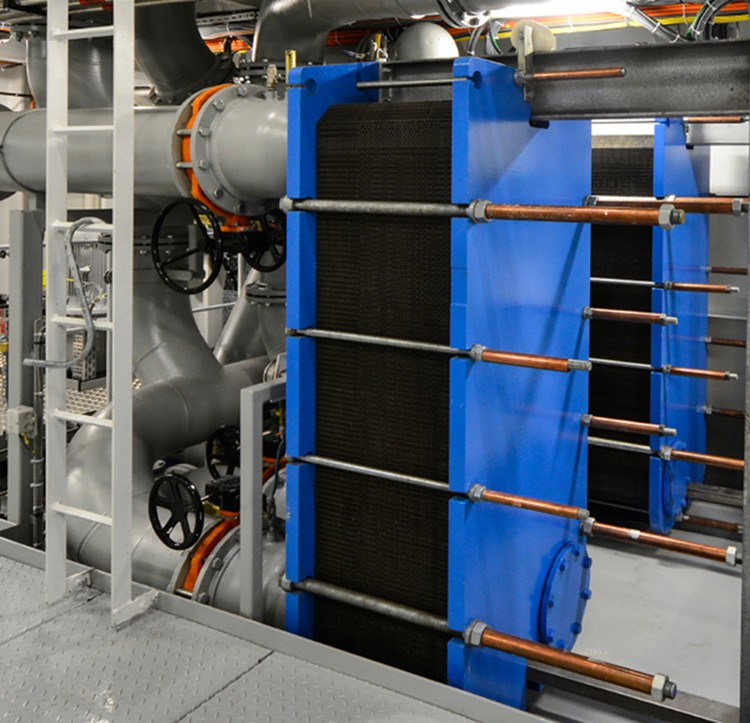

Our Farad line of PHE heat exchangers covers most applications with a wide range of capacities. They are suitable for cooling and heating in a range of industries such as marine, industrial, chemical processing, petrochemical, HVAC, power, pharmaceutical or food industry applications.

Material-Best plate heat exchanger for beer brewery

The materials of all PHE components have been carefully selected to meet the requirements for optimized performance and extended service life. Stainless steel is used for standard operations, and when sea water is involved, titanium is chosen to improve corrosion resistance.

quality

Our heat exchanger products meet the requirements of industry regulations and are guaranteed by a quality system recognized by a third party.

Selection Guide-Best plate heat exchanger for beer brewery

industry

Power plant central or auxiliary cooling

Chemistry

Food and beverage preparation

Pharmaceutical industry

Heating

Cooling

Condensation